The demand for sustainable packaging is rising faster than ever, and businesses are now searching for reliable alternatives that balance strength, affordability, and environmental responsibility. Among all the new-age materials, molded fiber products have become a practical choice for brands that want packaging to look good, perform well, and remain planet-friendly.

Made from natural fibers such as recycled paper pulp, sugarcane bagasse, or bamboo, molded fiber offers durability without relying on plastics. It has become a favourite across foodservice, retail, e-commerce, and other industries looking to reduce single-use waste. As more companies prioritise sustainability, the role of molded fiber packaging companies continues to grow worldwide.

Understanding Molded Fiber: What Makes It Unique?

Molded fiber is created by pressing natural plant-based fiber pulp into shapes using heated molds. This process produces sturdy trays, plates, bowls, containers, and protective packaging inserts.

Its biggest strength lies in versatility. Whether it is a compostable food container or a shock-resistant electronics insert, molded fiber adapts easily to different shapes and sizes.

Key qualities include:

- Naturally biodegradable

- Strong and lightweight

- Heat and oil resistant

- Customizable for branding

- Made from renewable and recycled materials

These traits make molded fiber products ideal for companies aiming for sustainability without compromising on performance.

Why Businesses Are Shifting Toward Molded Fiber Packaging

- A Natural Alternative to Single-Use Plastics

Many countries are phasing out plastic disposables. Molded fiber–made from paper pulp or plant waste–offers a clean, safe, and eco-friendly alternative. It breaks down naturally in the environment without leaving harmful residues.

- Excellent Strength for Everyday Use

Despite being made from natural materials, molded fiber is surprisingly durable. Foodservice businesses prefer it because it can handle heat, moisture, and pressure without losing shape.

- Safe for Food Contact

Restaurants, cafés, and cloud kitchens are moving toward compostable packaging. Molded fiber containers are food-safe and suitable for hot and cold dishes, making them a reliable choice for daily service.

- Lightweight Yet Protective

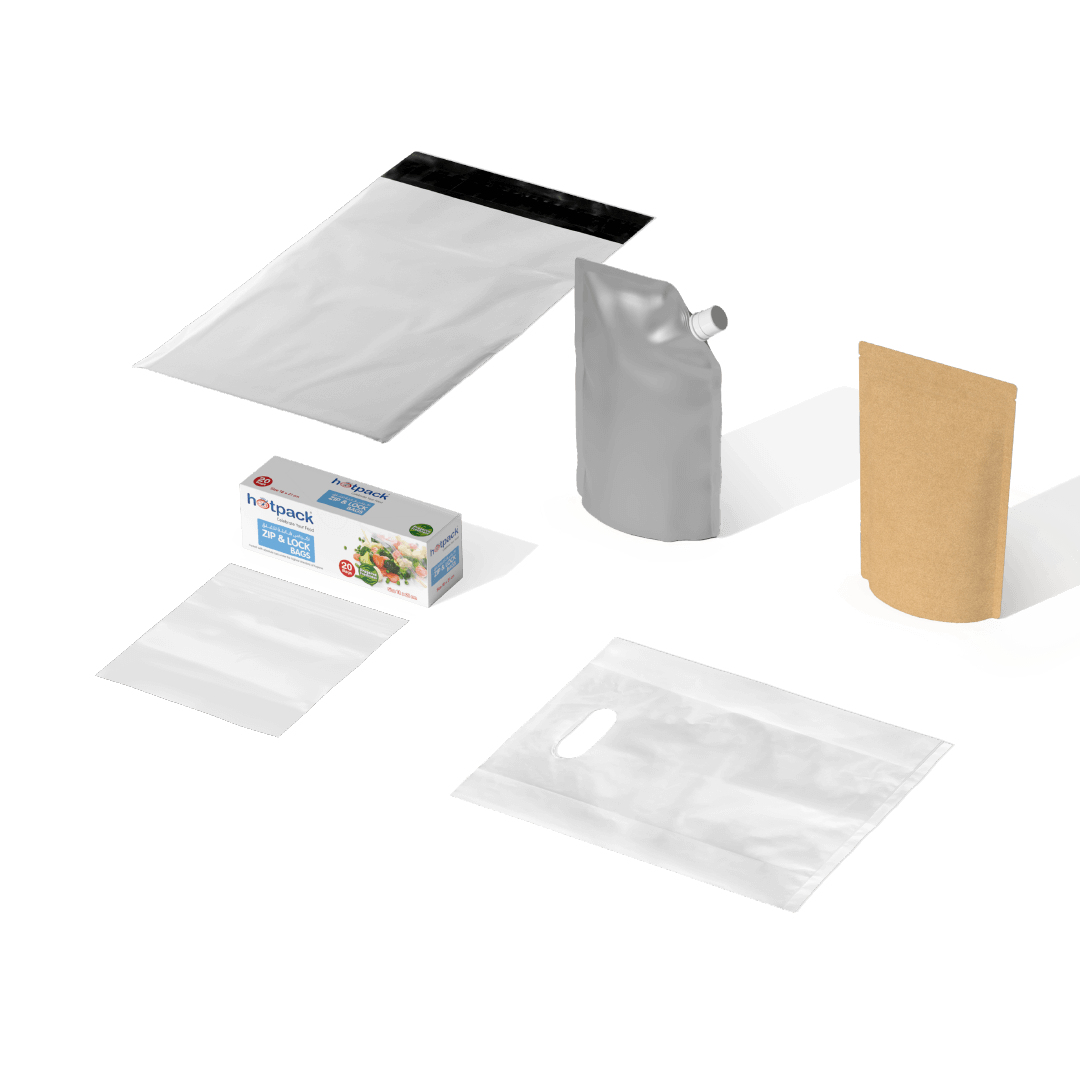

In retail and e-commerce, molded fiber inserts help protect fragile items like electronics, skincare, perfumes, and glassware. Lightweight packaging also reduces shipping costs, which is a major benefit for growing brands.

- Custom Shapes That Fit Brand Needs

One reason molded fiber packaging companies are becoming so essential is their ability to create custom-molded shapes. Businesses can choose specific sizes, textures, or branding requirements to match their needs. The result is packaging that feels premium and eco-conscious at the same time.

Popular Applications Across Industries

Foodservice & Takeaway Brands

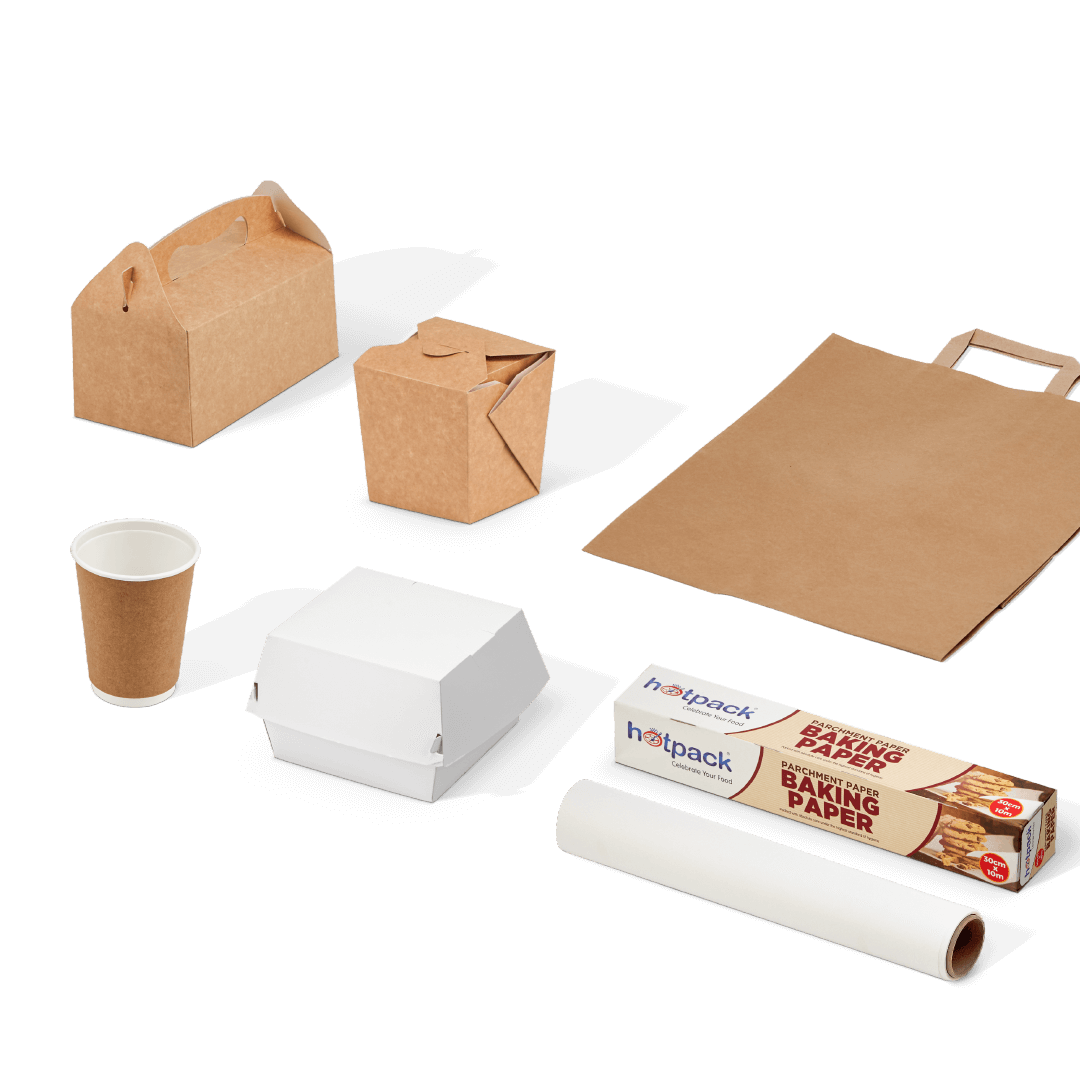

Molded fiber plates, bowls, and clamshell containers offer strength and convenience. They are widely used in restaurants, bakeries, cafeterias, hotels, and catering services.

Retail & Supermarkets

Pre-packed fruits, vegetables, bakery items, and ready-to-eat meals are often placed in molded fiber trays thanks to their natural look and reliable structure.

Electronics & Fragile Goods

Molded fiber inserts are shock-absorbent, making them ideal for electronics, glassware, lighting items, and delicate products.

Cosmetics & Personal Care Industry

Brands use molded fiber inserts and packaging trays for creams, perfumes, serums, and gift sets to achieve both elegance and sustainability.

E-commerce Shipping

As online retail grows, molded fiber packaging helps brands reduce breakage, improve customer experience, and support eco-friendly branding.

How Molded Fiber Is Made: A Simple Overview

The manufacturing process is designed to reduce waste and energy use:

- Collection of recycled paper or plant fibers

- Pulping and cleaning, where fibers are turned into thick pulp

- Forming, where the pulp is shaped using molds

- Pressing and drying, giving the product strength and structure

- Trimming and finishing for smooth edges and clean presentation

This process is efficient, clean, and more sustainable compared to plastic manufacturing.

Why Molded Fiber Is a Future-Ready Packaging Choice

As environmental regulations get stricter and consumer expectations shift, businesses need packaging that aligns with long-term sustainability goals. Molded fiber is not a trend, it’s a practical transition toward better materials, better branding, and a better future.

Its adaptability across industries ensures long-term demand and makes it one of the strongest eco-friendly solutions today..

Hotpack Global – Your Trusted Partner for Sustainable Fiber Packaging

Hotpack Global is one of the most reliable names in the packaging industry, offering strong and eco-friendly molded fiber solutions for businesses across foodservice, retail, e-commerce, hospitality, and more. Our molded fiber range is designed with quality, hygiene, and sustainability at the core, ensuring every product delivers durability and performance.

We provide a variety of trays, bowls, clamshells, and protective inserts suitable for hot and cold food, takeaway services, and retail packaging. With advanced manufacturing capabilities, consistent quality checks, and customer-focused service, Hotpack Global helps businesses move confidently toward cleaner and greener packaging choices. Choose Hotpack for dependable molded fiber solutions that support your growth and sustainability goals.

A Smarter Way Forward

Molded fiber has become a reliable choice for companies that want packaging that looks good, works well, and stays eco-responsible. As more industries adopt sustainable practices, molded fiber continues to lead the way with strength, safety, and design flexibility. In a world where responsible choices matter, molded fiber is one of the most dependable food packaging materials for businesses aiming to improve their environmental footprint.

FAQs

- What are molded fiber products commonly used for?

Molded fiber products are used in foodservice packaging, protective inserts, trays, bowls, clamshells, and retail displays. They provide strength, sustainability, and versatility, making them suitable for hot meals, takeaway food, fragile goods, and eco-focused businesses.

- Why are molded fiber options becoming so popular?

They are renewable, biodegradable, and safe for food contact. Businesses prefer them as they reduce reliance on plastics while offering excellent durability. Many companies trust molded fiber packaging companies for reliable and eco-friendly alternatives.

- Are molded fiber containers safe for hot food?

Yes. Molded fiber containers are heat-resistant and sturdy, making them safe for serving hot dishes. They do not release harmful chemicals and maintain their shape, which makes them ideal for restaurants and catering services.

- Can molded fiber packaging be customized?

Absolutely. Many manufacturers offer custom shapes, branding, and sizes to suit different business needs. This helps companies enhance their brand identity while using sustainable packaging.

- Are molded fiber products really eco-friendly?

Yes. They are made from recycled or renewable fibers, decompose naturally, and require less energy to produce than plastic alternatives. This makes them a responsible choice for businesses aiming for greener operations.