Sustainability has become more than just a buzzword, it’s a necessity in today’s food and retail industries. With growing concerns about environmental impact, businesses are actively shifting from single-use plastic-based packaging to eco-friendly solutions. One of the most popular alternatives leading this change is molded fiber products. Durable, versatile, and biodegradable, molded fiber packaging is making waves across industries, from restaurants to supermarkets.

This guide explores why molded fiber packaging is gaining momentum, its benefits, applications, and how it compares with other packaging materials.

What Are Molded Fiber Products?

Molded fiber products are made from recycled paper, cardboard, or natural fibers like sugarcane bagasse. They are molded into various shapes and sizes, making them suitable for trays, clamshells, plates, cups, and containers. Unlike traditional single-use plastic packaging, molded fiber decomposes naturally, leaving no harmful residues behind.

This packaging option is often manufactured using water-based processes where pulp is shaped into molds, dried, and finished to meet durability standards. It combines strength with eco-friendliness, making it an attractive choice for environmentally conscious businesses.

Why Molded Fiber Packaging Matters Today

- Environmental Concerns

Single-use plastic packaging contributes to landfills and ocean pollution. Molded fiber solves this by being compostable and biodegradable, reducing environmental strain.

- Government Regulations

Many countries are banning single-use plastics, pushing businesses to adopt alternatives. Molded fiber meets regulatory requirements without compromising usability.

- Consumer Preferences

Today’s consumers actively choose businesses that prioritize sustainability. Using molded fiber packaging enhances brand image and customer trust.

Benefits of Molded Fiber Products

1. Biodegradable and Eco-Friendly

Molded fiber products break down naturally, eliminating the long-term waste associated with plastics. Businesses can reduce their carbon footprint while ensuring their packaging aligns with eco-friendly values.

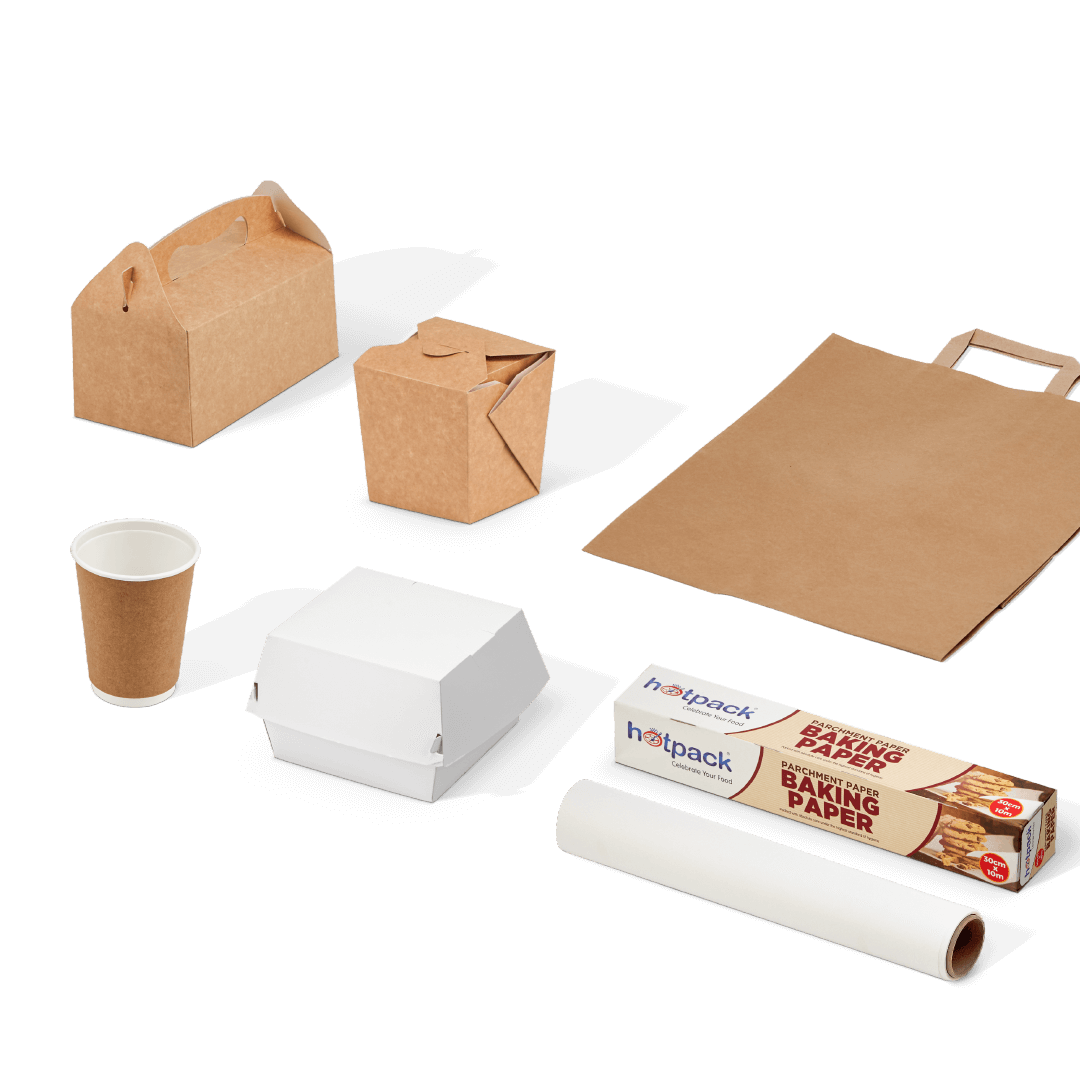

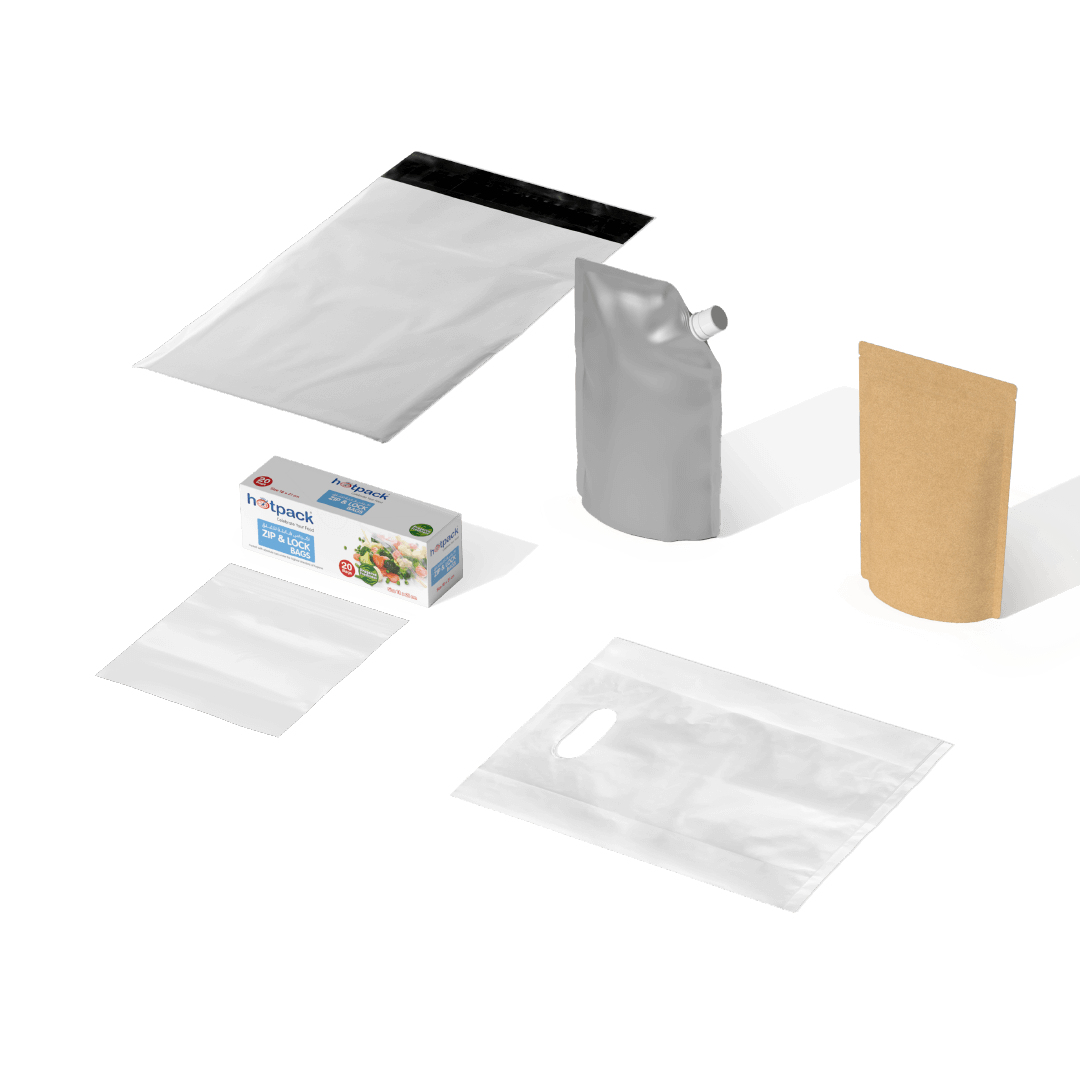

2. Versatile Applications

From food containers to protective packaging for electronics, molded fiber has a wide range of uses. Foodservice providers, especially quick-service restaurants and delivery businesses, rely on it for takeaway packaging.

3. Cost-Effective in the Long Run

While initial costs may be slightly higher compared to single-use plastic, the long-term benefits outweigh them. By adopting molded fiber, businesses avoid penalties related to single-use plastic bans and gain customer loyalty.

4. Customization Options

Leading molded fiber packaging companies provide tailored designs with branding, ensuring that packaging not only protects products but also represents the business identity.

5. Heat and Moisture Resistance

Molded fiber trays and clamshells can withstand hot, cold, and moist foods without losing shape, making them reliable for foodservice operations.

Industries Benefiting from Molded Fiber Packaging

-

Foodservice Industry

Restaurants, cafés, and catering services widely adopt molded fiber trays, bowls, and plates for eco-friendly food delivery and takeaway.

-

Retail & Grocery Stores

Supermarkets use molded fiber trays for produce, eggs, and bakery items. Its natural, rustic appearance also appeals to eco-conscious shoppers.

-

Electronics and Fragile Goods

Beyond food, molded fiber is also used in protective packaging for electronics, medical devices, and glassware. Its shock-absorbing quality makes it a safer option than single-use plastic foam.

-

Healthcare Sector

Hospitals and clinics use molded fiber for hygienic disposables, including trays and containers.

Future Trends in Molded Fiber Packaging

- Innovation in Design – Companies are experimenting with sleek, modern designs to replace traditional clamshells and trays.

- Combination Packaging – Pairing molded fiber with minimal single-use plastic films for sealing and visibility.

- Global Expansion – As single-use plastic bans increase, molded fiber will dominate global markets.

- Technology Integration – Improved production methods will lower costs and make fiber packaging more accessible.

Molded Fiber Products as a Game-Changer

The packaging industry is transforming, and molded fiber products are at the heart of this change. By offering eco-friendly, versatile, and cost-effective solutions, molded fiber packaging companies are setting new benchmarks in sustainability. For foodservice businesses, retailers, and manufacturers, this packaging option represents not just a trend but a necessity.

If you’re aiming to strengthen your brand while supporting the planet, molded fiber is an investment worth making. With durability, design flexibility, and environmental responsibility, it’s the ideal packaging solution for modern businesses.

In the long run, businesses adopting molded fiber will not only comply with regulations but also attract conscious consumers who care about the planet. It is the future of food packaging materials, ensuring both performance and sustainability.

Hotpack Global: Your Partner in Sustainable Packaging

At Hotpack Global, we combine global manufacturing expertise with a commitment to sustainability, offering world-class molded fiber solutions. As one of the most trusted names in the industry, we deliver packaging that balances innovation, hygiene, and eco-friendliness. Whether you run a restaurant, a supermarket, or a manufacturing unit, our range of molded fiber packaging is designed to meet your needs with reliability and quality.

From biodegradable trays and clamshells to innovative food containers, we ensure your business gets packaging that supports both performance and the planet. Choose Hotpack Global for packaging that truly makes a difference.

FAQs

Q1. What are molded fiber products commonly used for?

ANS- Molded fiber products are used for food trays, containers, plates, egg cartons, and protective packaging for electronics and fragile goods.

Q2. Are molded fiber products safe for food?

ANS- Yes, molded fiber packaging is food-grade, safe, and complies with hygiene standards. It can hold hot, cold, and moist food without issues.

Q3. Can molded fiber packaging be customized?

ANS- Absolutely. Many manufacturers offer custom sizes, branding, and designs to meet business-specific needs.

Q4. How long does molded fiber take to decompose?

ANS- Typically, molded fiber decomposes within 60–90 days in composting conditions, making it an environmentally responsible option.