In today’s competitive packaging industry, strength, cost-effectiveness, and environmental impact are vital considerations. One material continues to dominate in these aspects, corrugated material. Whether it’s for e-commerce shipping, takeaway containers, or retail product packaging, corrugated boxes offer businesses a reliable solution that balances durability and sustainability.

This blog explores what is corrugated packaging, how it differs from standard cardboard, and why it’s a preferred choice for both manufacturers and eco-conscious brands.

What Is Corrugated Material?

To understand the advantages of corrugated packaging, it’s important to first define what it is. Corrugated material consists of a fluted (wavy) inner layer sandwiched between two flat linerboards. This layered construction gives the material superior strength and cushioning compared to regular cardboard.

Corrugated sheets come in various types, such as single-wall, double-wall, or triple-wall formats, each offering a different level of durability depending on the product’s weight and shipping requirements.

What is a corrugated box? It’s more than just a regular box. Designed for performance, corrugated boxes are engineered to protect goods from impact, compression, and temperature fluctuations. They are widely used for packaging electronics, food products, household goods, industrial tools, and more.

The main difference between a regular cardboard box and a corrugated box lies in its multi-layered construction. This gives it higher resistance to damage, making it a dependable choice across various industries.

The Cardboard Misconception

People often confuse corrugated boxes with cardboard. However, understanding corrugated vs non corrugated cardboard is crucial for making the right packaging decisions.

- Non-corrugated cardboard (also known as paperboard) is a single-layered, thinner material used in items like cereal boxes, gift boxes, or lightweight retail packaging.

- Corrugated cardboard features the fluted layer that adds structure and strength, ideal for shipping and handling heavier items.

So while both are made from paper-based materials, their performance and application differ drastically.

Benefits of Corrugated Packaging

Let’s explore why what is corrugated packaging matters and why this type of packaging has become the go-to for businesses around the world:

1. Superior Strength & Protection

The fluted design provides structural integrity, cushioning against shock, and resistance to crushing. This makes corrugated packaging ideal for transporting fragile or heavy items.

2. Lightweight Yet Durable

Despite its strength, corrugated packaging is surprisingly lightweight, reducing transportation costs and carbon emissions, key for environmentally conscious businesses.

3. Eco-Friendly Choice

Most corrugated materials are recyclable and made from renewable sources. Many businesses are now switching to corrugated material as a sustainable alternative to single-use plastic-based options.

4. Customizability

Corrugated boxes can be manufactured in various shapes, sizes, and strengths. This flexibility makes them suitable for packaging everything from groceries to electronic gadgets.

5. Branding Potential

Modern cardboard box manufacturing techniques allow for high-quality printing directly on corrugated surfaces, making it easy for brands to add logos, product information, and eye-catching designs.

Applications Across Industries

The versatility of corrugated packaging cannot be overstated. Some of its most common applications include:

- E-commerce Shipping Boxes: Ensuring safe delivery of goods ordered online.

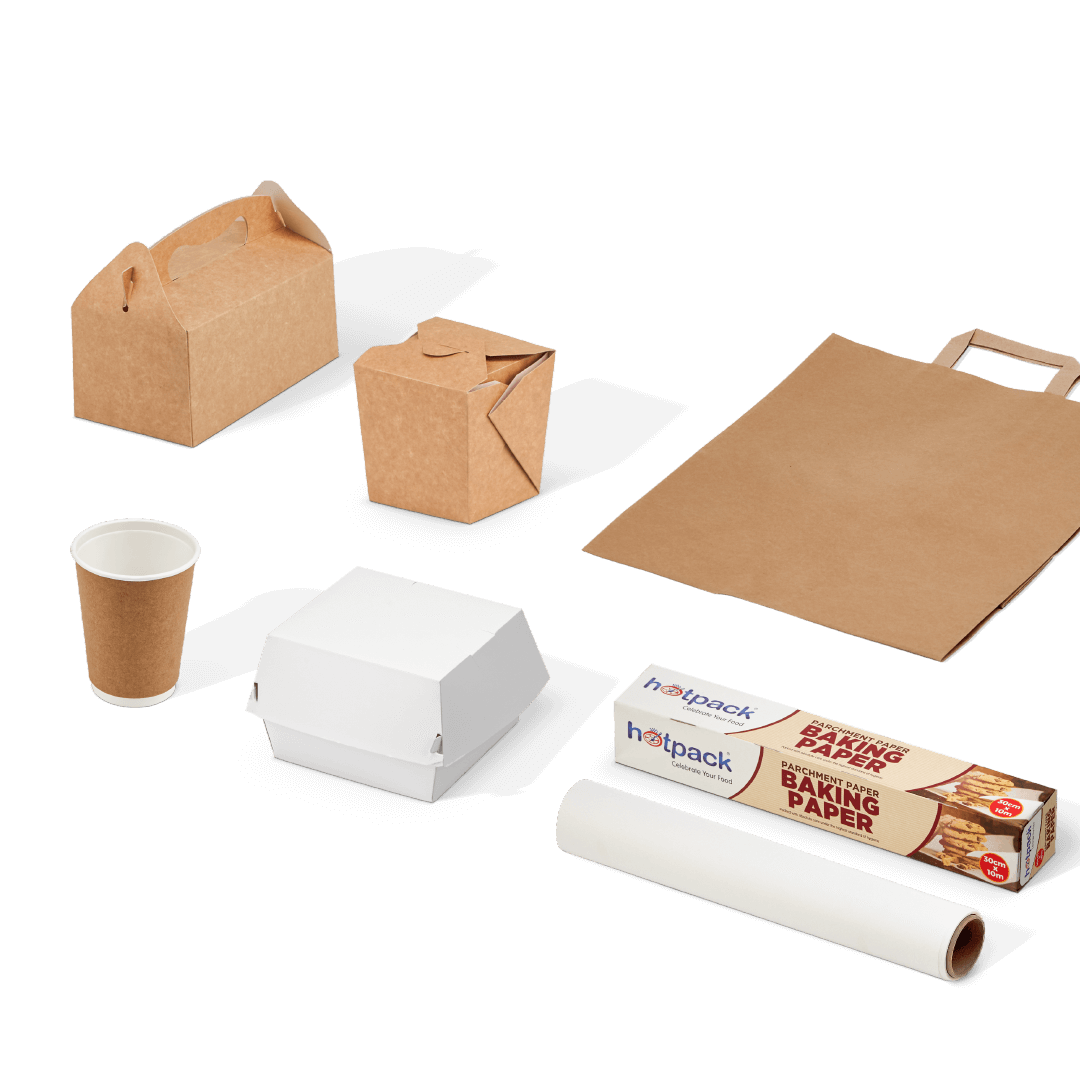

- Food & Beverage Packaging: Corrugated pizza boxes, take-out containers, and fruit/vegetable crates are just a few examples.

- Retail Display Units: Corrugated materials are also used to create point-of-sale (POS) displays in retail environments.

- Industrial Packaging: Used for machine parts, hardware, and other heavy-duty items, especially in export packaging.

Innovations in Cardboard Box Manufacturing

As packaging needs become more complex, cardboard box manufacturing has evolved with technology. Today, manufacturers offer advanced features such as:

- Water-resistant coatings

- Insulated liners for temperature-sensitive goods

- Dual-purpose packaging (e.g., display and shipping)

- Tear strips and easy-open designs for convenience

This progress ensures that corrugated packaging remains a leader in innovation, convenience, and performance.

Choosing Between Corrugated and Non-Corrugated Packaging

When deciding between corrugated vs non corrugated cardboard, consider the following:

- If you’re packaging delicate or heavy items or need long-distance shipping, corrugated is the superior choice.

- For lighter items with minimal handling, such as cosmetics or dry snacks, non-corrugated cardboard may suffice.

Ultimately, your product, brand values, and logistics requirements should guide your choice.

Sustainability Considerations

One of the strongest arguments for corrugated materials is their recyclability and reduced environmental footprint. Since corrugated packaging often includes post-consumer recycled content, businesses using it can proudly market themselves as eco-conscious.

This is particularly important for companies aiming to align with the growing demand for green practices, especially in regions with strict sustainability regulations.

A Smarter Way to Package

When it comes to protecting products, enhancing sustainability, and boosting brand image, corrugated materials stand out. Understanding what is a corrugated box, its advantages over non corrugated cardboard, and its applications in modern cardboard box manufacturing allows businesses to make informed choices that impact both the bottom line and the environment.

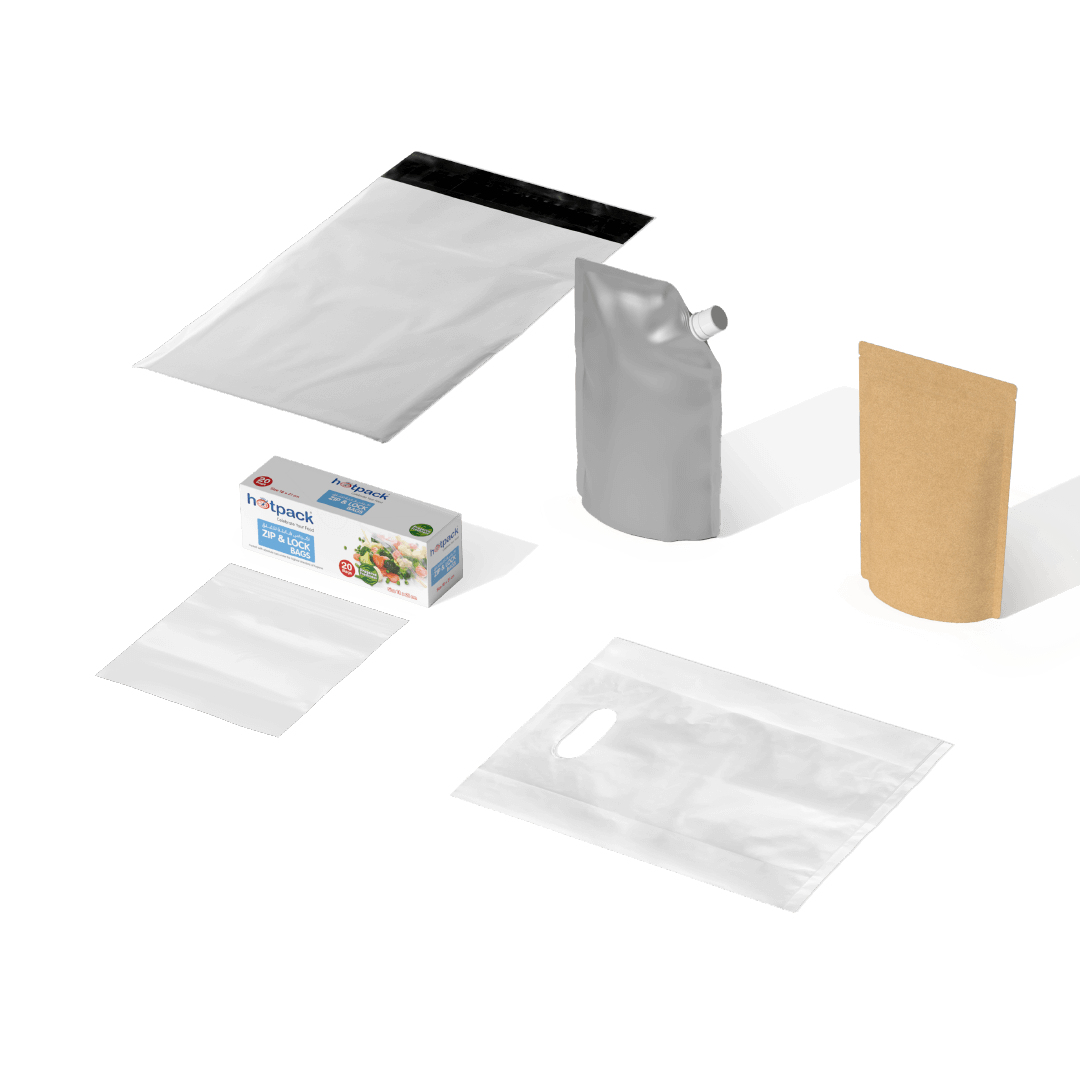

Hotpack Global: Your Packaging Partner

Hotpack Global is a trusted name when it comes to reliable, sustainable, and high-performance packaging solutions. Whether you need corrugated cartons for shipping, food-grade containers, or display-ready retail boxes, Hotpack delivers premium quality with speed and precision. As a leading packaging manufacturer, our solutions cater to industries ranging from hospitality to e-commerce, ensuring durability and eco-compliance at every step.

From custom sizing to bulk orders, we offer unmatched flexibility in design and application. Choose Hotpack Global for all your corrugated packaging needs and partner with a company that understands both innovation and sustainability.