Food safety and sustainability are two of the biggest concerns in today’s food industry. From restaurants and supermarkets to catering businesses and takeaways, packaging plays a critical role in ensuring food remains fresh, safe, and convenient to transport. Among the many options available, plastic food container solutions continue to dominate the market due to their versatility, cost-effectiveness, and durability. But not all plastics are created equal. Understanding food-grade plastics and their benefits can help businesses make smarter, safer, and more sustainable packaging choices.

What Are Food-Grade Plastics?

Food-grade plastics are materials designed and manufactured specifically for packaging, storing, or handling consumable goods. Unlike regular plastics, these are tested for safety to ensure they don’t leach harmful chemicals into food. Their formulation complies with strict international food safety standards, making them a reliable choice for businesses across industries.

Types of Food-Grade Plastics Commonly Used in Packaging

Not every type of plastic is suitable for food contact. Some of the most widely used food-safe plastics include:

- Polyethylene Terephthalate (PET): Lightweight and recyclable, often used in beverage bottles and salad containers.

- Polypropylene (PP): Known for heat resistance, ideal for microwavable food trays and containers.

- High-Density Polyethylene (HDPE): Strong, impact-resistant, and safe for milk jugs, bottles, and packaging bags.

- Low-Density Polyethylene (LDPE): Flexible and durable, often used in wraps and squeeze bottles.

- Polystyrene (PS): Common in disposable cutlery and food trays, though many businesses are shifting to eco-friendlier options.

These materials balance safety, performance, and cost-effectiveness, making them a top choice for food packaging.

Why Food Businesses Prefer Plastic Containers

A plastic food container is more than just a vessel for carrying meals; it offers tangible advantages to both businesses and consumers:

- Durability & Protection – Strong resistance to impact keeps food safe during transport.

- Cost-Effective – More affordable than alternatives like glass or metal packaging.

- Lightweight & Convenient – Easy to carry and store, making them practical for takeout and delivery.

- Hygienic & Food-Safe – Manufactured under strict standards to prevent contamination.

- Customizable – Available in various sizes, designs, and colors to match brand identity.

Sustainable Food-Grade Plastics: Moving Toward Eco-Friendly Packaging

While plastics have long been criticized for their environmental impact, modern technology has made significant improvements. Today, many packaging companies are focusing on recyclable and biodegradable plastics that reduce waste and support sustainability goals. For instance:

- Recyclable PET and PP containers reduce landfill burden and can be reused in new products.

- Biodegradable plastics made from renewable resources like corn starch are increasingly adopted for short-use applications.

- Lightweight designs cut down on raw material consumption and lower transportation emissions.

These innovations are helping businesses align with both customer expectations and environmental regulations.

Best Practices for Choosing Food-Grade Plastic Packaging

Businesses that rely on packaging should carefully evaluate their options. Here are key factors to consider when selecting food-grade plastics:

- Type of Food: Hot, cold, or oily foods may require different single-use plastics for safe storage.

- Transportation Needs: Long-distance deliveries benefit from sturdy, leak-resistant containers.

- Sustainability Goals: Eco-friendly plastics or recyclable containers help businesses improve their green image.

- Compliance & Safety: Always ensure packaging meets FDA, EU, or other local food safety certifications.

- Cost Efficiency: Bulk purchasing and working with a trusted partner can reduce overall expenses.

Hotpack Global: Your Trusted Partner in Food Packaging

Food-grade plastics are indispensable in the modern foodservice and retail sectors. From durability to safety, they offer unmatched benefits that make them the backbone of global food packaging. However, responsible usage and a focus on sustainable innovations are essential to ensure long-term success. When sourcing packaging solutions, businesses should always partner with a trusted plastic products supplier who offers certified food packaging materials designed for safety, reliability, and environmental responsibility.

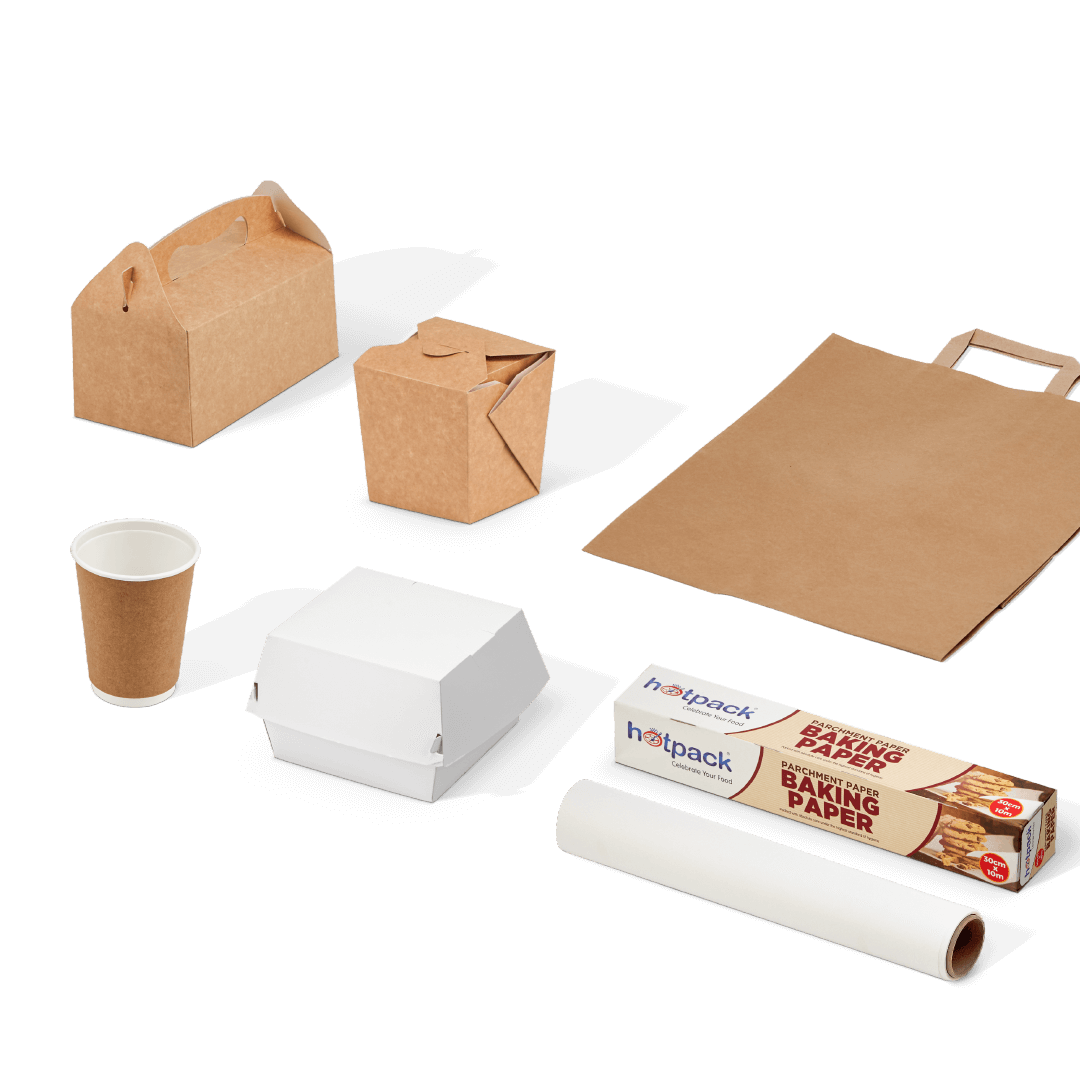

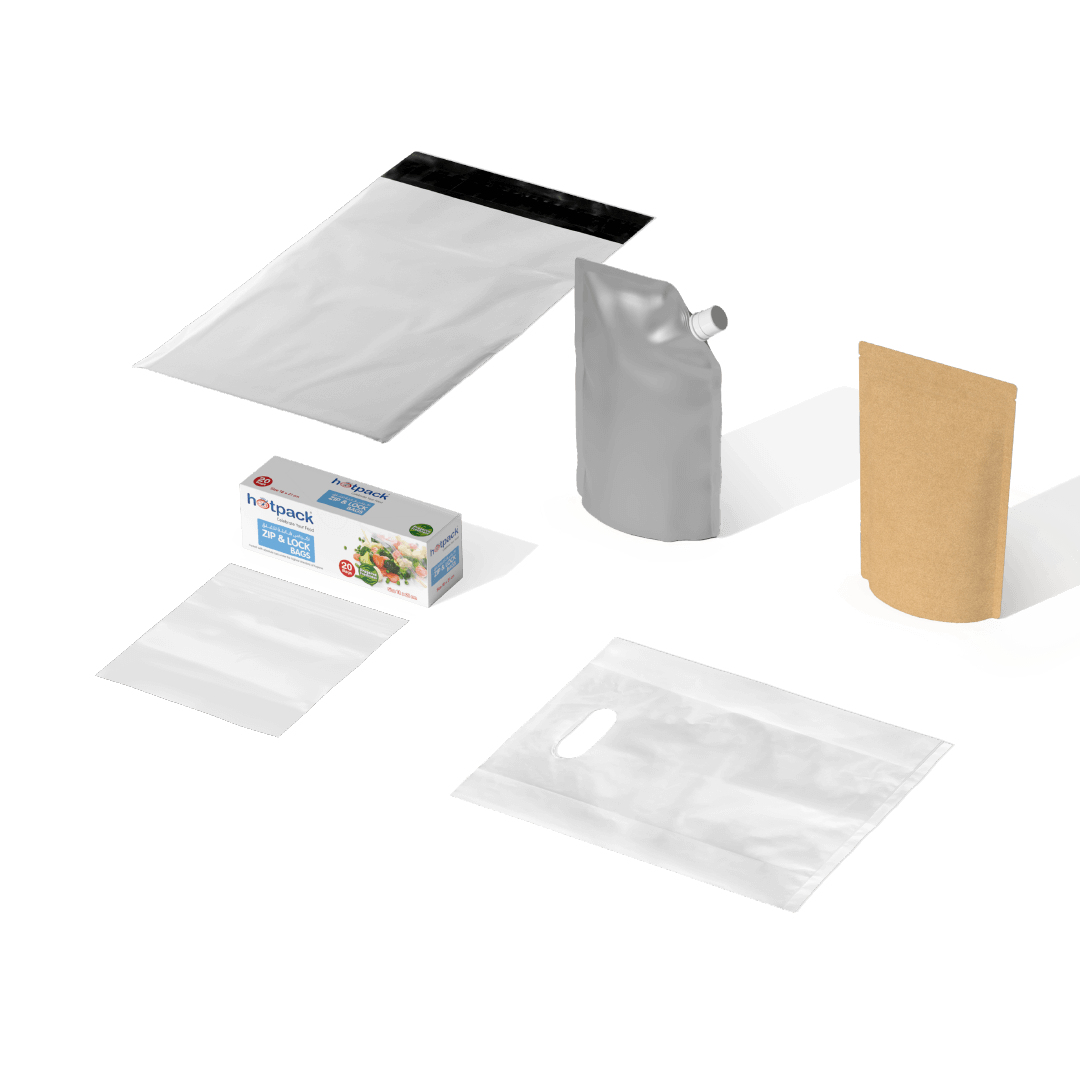

Hotpack Global is a world leader in providing innovative packaging solutions tailored to modern business needs. With a diverse portfolio that includes eco-friendly plastics, paper-based products, and flexible packaging, Hotpack ensures quality, safety, and sustainability at every step. Whether you run a small café or a large foodservice chain, Hotpack offers custom solutions that combine global manufacturing strength with local relevance. Our commitment to premium quality, food safety, and environmental care makes us the preferred choice for businesses across the globe. Partner with Hotpack today and experience packaging that supports your growth while caring for tomorrow’s world.

FAQs

Q1. What is a food-grade plastic food container?

ANS- A food-grade plastic food container is made from materials tested to ensure they don’t release harmful chemicals into food. They comply with international safety standards and are widely used for storage, delivery, and retail packaging.

Q2. Are plastic containers safe for hot foods?

ANS- Yes, certain plastics like polypropylene (PP) are heat-resistant and suitable for microwavable meals. Always choose containers labeled food-safe and heat-safe for hot dishes.

Q3. Can food-grade plastics be recycled?

ANS- Many food-grade plastics, such as PET and PP, are recyclable. Businesses should check local recycling facilities and choose containers designed with eco-friendly and recyclable materials.